Hardware & Making

Artistic PCB Design and Fabrication

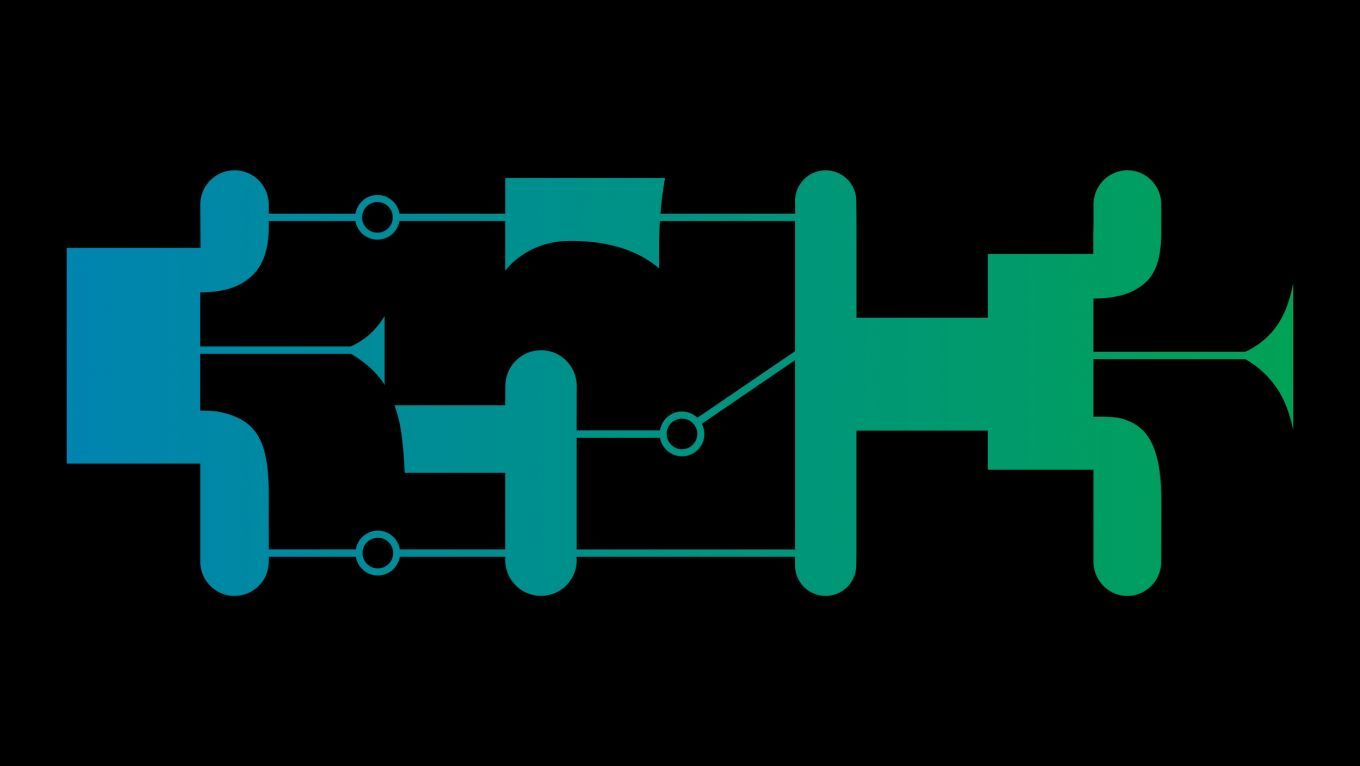

From doodle to manufacture: how I make mechanically complicated PCBs.

When a electrical device needs to be a piece of art or used as a mechanical component, a printed circuit board is more than a piece of fiberglass with wires embedded in it. In chemical engineering applications internal holes which allow fluids to be transported through the PCB need to be placed in complex precise patterns. As art, holes can be used to create positive and negative space, allowing you to see a charlieplexed LED display as a snowflake. Creating complex shapes in PCB design software is difficult to impossible. However, it is easy in CAD software. In this talk I will present the project workflow I use to design and manufacture my PCBs. Additionally, I will discuss the problems I have run into during manufacturing and how these problems were resolved.

Making electrical-artistic and electrical-mechanical PCBs adds steps and complications to the usual PCB fabrication process. In this talk I will go over my project workflow and discuss how and why I do each step. I will also discuss problems I have run into during both the design and the manufacturing process.

An overview of my workflow is as follows:

Make a sketch of what the final PCB will look like and what it will do.

Make a schematic of the electronics (kicad).

Assign footprints to the electrical components (kicad).

Check the manufacturers webpage for the design criterion on internal cuts.

Create a CAD file of the PCB outline (no electrical connections) (fusion 360/solidworks etc).

(optional) Conduct multiphysics simulations of the PCB outline, to find an optimal design (comsol etc).

Make boxes to represent the footprints of the electrical components and place these where you want them to be on the final PCB (fusion 360/solidworks etc).

Think about how the boards will be panelized and insert mouse bites/tabs for V-cuts as needed (fusion 360/solidworks etc).

Export a 2D drawing of the PCB including the components.

Make a PCB file with all the components (kicad).

Import the 2D drawing of the PCB as the edge cuts in the PCB file (kicad).

Place electrical components in the correct location and delete the edge cuts which are just being used as markers (kicad).

Use a routing software to connect components or connect these manually.

(optional) Panelize the boards by making a new PCB file and importing the single PCB.

Export the gerber files.

Check that the outlines are correct in the gerber files and clean up machining code if necessary.

Upload files to manufacturers webpage and include an image of which places should be milled out.

Common problems have included:

V-cuts on non-rectangular PCBs.

Keepout zones on internal edge-cuts.

Gerber file generation errors caused by internal edge cuts and pannelization.

Some manufacturers do not do internal edge cuts.

Boards are mechanically weakened by internal cuts.

Weitere Infos

| Format | lecture |

|---|---|

| Sprache | Englisch |

Weitere Sessions

| 27.12.18 |

While a lot of projects are currently developing their own processors, mostly as open source in Verilog, VHDL or even Chisel, we miss the free process that actually manufactures these chips. So we're developing the "Libre Silicon" project, a portable semiconductor manufacturing process and technology, using only free and open source tools: We would like to introduce the project, who we are, what we are doing and where we are now.

|

| 27.12.18 |

<a href="https://www.sigfox.com/">Sigfox</a> is an emerging low-power wide-area network (LP-WAN) technology for IoT devices, comparable to <a href="https://lora-alliance.org/">LoRa</a>. This talk recounts my analysis of Sigfox's radio protocol and presents an open reference implementation of an alternative Sigfox protocol stack. It confirms that while Sigfox ensures authenticity and integrity, transmitted payloads are not confidential. This presentation is targeted at a technical audience with ...

|

| 27.12.18 |

Encoding or decoding random radio-waveforms doesn't need incredible expensive hardware anymore which offers new possibilities for building up over-the-air communication systems. There are Software Defined Radios providing affordable cellular radio to remote villages, Community Radios are using SDR to build up digital radio networks and other cool stuff. Some basic knowledge what is going on in SDR Hard/Software as the influence of the samplerate, I/Q-data of the math behind the waterfall-diagram ...

|

| 27.12.18 |

Open Source firmware ist ein Begriff seit 1999 wo LinuxBIOS (coreboot) und u-boot als Projekt starteten. Heute nach fast 20 Jahren ist endlich Open Source firmware bei den Herstellern von Hardware angekommen: Google Chromebooks - coreboot Facebook Open Compute Hardware - coreboot / LinuxBoot Purism Laptops - coreboot Microsoft Olympus - TianoCore Microsoft Surface - TianoCore IBM Power 9 - Hostboot / Skiboot ARM Hardware - ARM Trusted Firmware Intel Minnowboard - TianoCore, coreboot A lot ...

|

| 28.12.18 |

The <a href="http://symbiflow.github.io">SymbiFlow project</a> aims to be the "GCC of FPGAs" - a fully open source toolchain supporting, multiple FPGAs from different vendors. Allowing compilation from Verilog to bitstream without touching vendor provided tools, it includes support for large modern FPGAs like the Lattice ECP5 and Xilinx 7 series. These FPGAs can be used for things previously out of reach of FOSS tools, things like high resolution video and many gigabit networking. We have also ...

|

| 28.12.18 |

Project IceStorm provides the first end-to-end open source FPGA toolchain, was originally presented at 32c3, and only targetted Lattice iCE40 FPGAs. nextpnr is the next big step for open source FPGA tools, providing a retargetable open source FPGA place-and-route tool that will enable open source flows for many different FPGAs from many different vendors.

|

| 28.12.18 |

Teaching beginners how to program is often <i>hard</i>. We love building programs, and seeing our loved ones struggle with this is painful. Showing them how to copy-paste a few example programs and change a few parameters is easy, but bridging from there to building substantial programs is a different game entirely. This talk is about how to teach programming successfully, through comprehensible <i>design recipes</i>, which anyone can follow, using languages and tools designed for beginners. ...

|